BLOG

In the demanding environment of the refractory industry, where intense thermal processes are common, having the right materials is a key factor. Not only do they directly influence operational efficiency, but they can also determine the technical and economic viability of the entire plant. This is why the selection of these materials must be made thoughtfully, considering both performance and durability.

Shotcrete technology for industrial refractory applications has made significant strides in recent years, becoming a reference technical solution compared to traditional methods such as vibrocasting or conventional guniting. This article by Alfran explains the main innovations developed, focusing on the evolution towards greater strength and efficiency, and how Alfran is leading this technological shift.

From the introduction of systems like High Gun® and Gunmix®, to developments with nanotechnology such as the Drytech® range, the new materials and installation methods have allowed for substantial improvements in the compactness, homogeneity, and durability of refractory linings. These solutions are targeted at high-demand sectors like cement, steel, diesel, and energy, where continuous operation and reducing downtime are crucial for profitability.

This advancement extends beyond the product characteristics and into the installation approach. Systems like Alfranpump® enable concrete to be installed more quickly, with fewer workers, and under better safety conditions. These developments not only meet a technical need but also reflect Alfran’s commitment to continuous innovation and protecting the core of the industry.

The Evolution of Shotcrete: Beyond the Conventional

For decades, conventional guniting was the standard method for applying refractory materials in high-temperature industries. However, it had significant limitations: high rejection rates, loss of fine particles, and, above all, inferior mechanical performance compared to methods like vibrocasting. With the advent of high-pressure guniting and the Gunmix® system, this scenario has changed radically.

The key to this evolution lies in the advanced design of projection equipment and optimized formulations with lower cement content and superior compactness. These advancements allow for a homogeneous projection with a significant reduction in open porosity, resulting in much more efficient thermal and mechanical performance. The electronic control of the process via intelligent modules ensures installation meets demanding parameters, improving both quality and traceability of the work carried out.

Industrial Applications of New Refractory Concretes

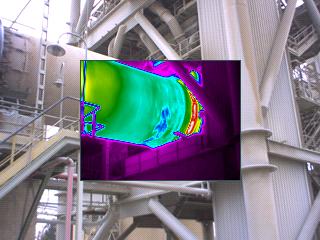

Shotcrete technology for industrial refractory applications is designed to adapt to a wide range of operational environments. In the cement industry, for example, its application in critical areas such as heads, entrance arches, and coolers has shown a significant improvement in the service life of linings. Success stories such as the Drytech® range in cement kilns have achieved reductions of up to 50% in CO₂ emissions during drying, as well as a decrease in the risk of explosions.

In steelmaking and energy, the materials developed by Alfran can withstand extreme conditions of abrasion, thermal shock, and impact. Thanks to sol-gel formulations, the microstructures obtained offer low porosity and high dimensional stability even at temperatures above 1500°C. This represents a key competitive advantage for processes such as casting or biomass boilers, where unplanned interruptions can lead to significant economic losses.

Benefits of New Shotcrete Technologies

Among the main benefits are improvements in mechanical strength and thermal efficiency, but also logistical and safety aspects. Solutions like High Gun® and Gunmix® offer installation speeds up to five times faster than vibrocasting, with material losses under 10% and drastically reduced drying times. This allows our clients to resume operations more quickly and with fewer risks.

The Alfranpump® system has transformed the way high or hard-to-reach work is performed. Its high-pressure pumping technology eliminates the need for lifting heavy loads, reducing the number of workers required and significantly lowering workplace accidents. Since the materials, like those from the Drytech® range, have no expiration date, stock management is optimized, and loss

In today’s demanding industrial environment, characterized by the constant need to optimize processes, reduce costs, and minimize environmental impact, choosing the right refractory coating system has become a strategic decision. Such choices not only affect the durability and safety of equipment but also directly influence energy efficiency and the sustainability of operations. Drytech refractory coatings stand out as a cutting-edge solution designed to address these challenges comprehensively.

The development of the Drytech range by Alfran reflects a clear approach: to offer unshaped refractory materials capable of withstanding extreme thermal conditions, with exceptional resistance to thermal shock, abrasion, and chemical attack, while also significantly reducing drying times and energy consumption. This technology is based on a ceramic bond system, free from cement, which eliminates the presence of chemically bound water and allows for greater efficiency during installation and commissioning.

In this article, Alfran explains in detail the key benefits of Drytech refractory coatings, highlighting their positive impact on productivity, sustainability, and operational management in industries such as cement, steel, energy, and oil & gas. These materials represent not just a technological evolution, but a true transformation in the way industrial refractory coatings are conceived.

Faster Drying and Operational Efficiency

One of the most valued aspects by our clients is the ability of Drytech concretes to enable faster and safer drying. Unlike conventional refractories with high cement content, Drytech technology does not contain chemically bound water. This means that all the liquid in the mix can be removed quickly and in a controlled manner at temperatures as low as 100°C.

This simplified process has several direct implications. First, it drastically reduces equipment startup time, which is crucial in contexts where technical shutdowns affect production and revenue. Second, it reduces the risk of explosions due to steam pressure, providing greater safety guarantees during critical drying phases.

In projects where speed is crucial, such as scheduled shutdowns or urgent maintenance, having a coating system that reduces drying times without compromising quality is a significant competitive advantage. Alfran has seen firsthand how this efficiency positively impacts the operational indicators of its clients, particularly in thermally demanding sectors like cement and steel.

Reduction of Energy Consumption

Energy efficiency is now a priority for all industries, both for economic and environmental reasons. In this context, Drytech materials offer up to a 50% reduction in energy consumption during drying, compared to conventional cement-based materials. This is because they require lower temperatures and less time to reach optimal service conditions.

With greater permeability, Drytech products allow for more efficient release of steam generated during drying, which means less internal pressure and, therefore, lower energy use to force this release. As a result, fewer resources are required to achieve operational conditions, optimizing the use of heating systems.

The benefit isn’t just energy-related. This reduction also translates into a lower need for auxiliary infrastructure (such as kilns or intensive heating systems), which leads to lower investment and less technical complexity during coating installation. For many industrial plants, this savings represents a direct and positive impact on their operational costs.

Sustainability and Emission Reduction

Aligning industrial production with sustainability criteria is an unavoidable need. Drytech refractory coatings actively help reduce the environmental footprint of facilities due to their low impact during the drying phase and increased durability during operation.

By reducing energy consumption, they also lower CO₂ emissions. This effect is particularly relevant in the context of the energy transition happening in sectors such as cement, where environmental regulations are becoming increasingly strict. The fact that these materials do not contain cement (one of the most carbon-intensive industrial products) further contributes to the sustainability of the process.

The greater durabi