Thermal engineering is a branch of engineering that studies phenomena related to the generation, transfer, conversion, and utilization of thermal energy. Its goal is to ensure the efficient control of heat in industrial systems, optimizing performance, improving durability, and reducing environmental impact.

At Alfran, specialists in refractory solutions, thermal insulation, and industrial fireproofing, we understand that the correct application of thermal engineering is essential to ensure the success of each of our projects. Therefore, we integrate this discipline from the early phases of analysis and design to the execution and maintenance of installations.

What is Thermal Engineering?

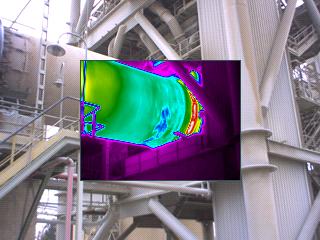

Thermal engineering involves the study of all processes in which heat plays a fundamental role. It includes the design of heat generation and transfer systems, the selection of materials suitable for withstanding high temperatures, and the optimization of industrial processes that require thermal control, such as melting, drying, or combustion.

In the industrial field, proper thermal management allows for:

- Increased energy efficiency of processes.

- Prolonged equipment lifespan.

- Reduced pollutant emissions.

- Minimization of risks of structural damage due to thermal shock or chemical attacks.

How Alfran Applies Thermal Engineering in Its Projects

For over 100 years, Alfran has integrated thermal engineering as a fundamental pillar of its solutions for sectors such as cement, aluminum, steel, oil & gas, energy, and copper. Our strategy is based on combining innovation, technical knowledge, and results-oriented goals.

Some specific ways in which we apply thermal engineering in our projects include:

- Selection of Advanced Materials

We use state-of-the-art refractory concretes, such as the Drytech® and Clean® ranges, designed to offer high resistance to thermal shock, chemical attack, and abrasion. These materials optimize the thermal performance of equipment and minimize risks during startup and operation phases. - Design of Customized Solutions

We tailor each project to the client’s specific needs by conducting a detailed analysis of operating thermal conditions. For example, in rotary cement kilns or aluminum recycling furnaces, we develop linings that reduce heat losses and extend production cycles. - Efficient Installation Technologies

We apply innovative technologies such as alfranpump®, which allows the installation of large volumes of refractory material with high quality, shorter construction times, and maximum safety. This not only optimizes the installation process but also improves the thermal efficiency of the final lining. - Development of Composite Materials

For applications requiring extreme mechanical and thermal resistance, such as in steel manufacturing, we use Steel-tech® products, ceramic-metallic materials that combine high refractoriness and resistance to abrasion. - Commitment to Sustainability

Our products and installation systems are designed to minimize energy consumption and CO₂ emissions. This results in benefits for both our clients and the environment.

At Alfran, we do not conceive a project without proper thermal management. Thermal engineering enables us to design more durable, efficient, and environmentally friendly solutions. We invest in innovation and technical knowledge as key tools to protect the heart of our clients’ industries.

The rigorous application of thermal engineering in our projects reflects our commitment to excellence, safety, and sustainability.