Refractory Materials: Specialists in Industrial Solutions

We have over 90 years of experience as a leading company in the manufacture and installation of heat-resistant concrete for kilns, boilers, and transportation elements for any industry requiring coatings designed to withstand high temperatures and physical-chemical attacks.

Refractory material solutions

We are a company specializing in refractory materials with extensive experience in the industry. Our services range from manufacturing to installation and maintenance, ensuring efficiency and durability.

Installation of Refractory Materials

We offer customized and highly specialized refractory installation services. Our advanced techniques ensure proper application and maximum durability of the material.

Refractory Repairs and Maintenance

We perform fast and efficient refractory repairs, minimizing downtime. Our expert team is trained to repair all types of damage to refractory linings.

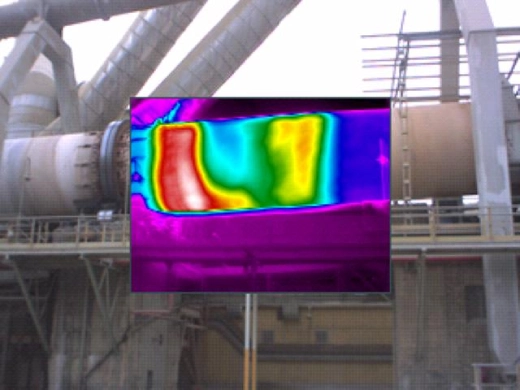

Diagnostics and evaluation of linings – Thermographic Analysis

Infrared thermography is a tool that has become widespread over time, in industrial preventive and predictive maintenance.

It exploits the properties of infrared radiation to draw useful conclusions about the condition of the equipment under test. Inspections require less time than repairs, especially if carried out with a thermal camera.

Monitoring equipment performance with thermal imaging cameras can reduce the likelihood of unplanned downtime due to equipment failure, reduce reactive maintenance fees and equipment repair costs, and extend the life of industrial machinery assets.

Thermal imaging is excellent for detecting non-uniformity in equipment, indicating hot and cold spots in surface temperature by capturing infrared images.

Types of refractory materials

ACID REFRACTORIES

Ideal for specific environments where chemical resistance is required, mainly manufactured from silica.

BASIC REFRACTORIES

Made primarily from magnesium, they guarantee resistance to high temperatures and extreme chemical conditions.

NEUTRAL REFRACTORIES

Versatile materials such as alumina refractories that offer excellent mechanical and chemical resistance.

Technical characteristics of our materials

High resistance to high temperatures

Our materials offer exceptional performance even under extreme thermal conditions.

Low thermal conductivity

We ensure efficient insulation that reduces energy losses and improves performance.

Chemical inertia

We guarantee that our materials maintain their properties even in highly corrosive environments.

Low expansion coefficient

Our products remain dimensionally stable, ensuring less wear and tear and a longer service life.

PATENTED SYSTEM

We have developed our own patented system, ALFRANJET, generally called SHOTCRETING, which involves 100% wet-mix pumping and high-speed spraying of heat-resistant concrete with and without aluminous cement, and without dust or waste. We have a long list of international references from multinational clients.

Frequently asked questions about refractory materials at Alfran

We manufacture a variety of prefabricated refractory shapes tailored to each specific industrial need.

Our refractory dry-out process is carried out in a controlled manner to ensure stability and operational safety.